Electromagnetic Motor Project

Project Objectives

This project page details my work in my Senior Design project, where we were tasked with the redesign of a rotor that would be created through metal additive manufacturing. The methods we chose for improving the motor were to improve its geometry through topology optimization, and to improve the materials of the motor through materials selection. My role in this senior design group was to create the new designs using topology optimization, and to select the materials used in the designs that would produce the best blend of performance for soft magnetic materials. My teammates in the senior design group were responsible for performing finite element simulation on the designs to make sure it could withstand loading, as well as creating electrical simulations to make sure that it would spin properly without producing too much eddy current.

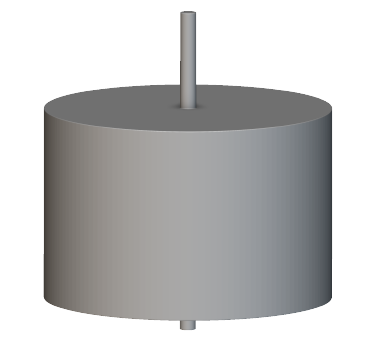

The rotor design above was a recreation of the rotor that came in the motor we purchased, which was a brushless DC motor. I took great care in creating the CAD file for this, as it was very important that the profile of the original rotor was exact so that all topology optimization techniques applied to it would be well informed by the original body and geometry.

Project Outcomes

The outcome of this project was that final designs for the new rotor were created and checked for viability using resin 3D printing. We were not able to complete the rotor print using metal because we lacked argon gas for the inert print environment, but we were still able to make sure that the final design could be 3D printed successfully, which it was!

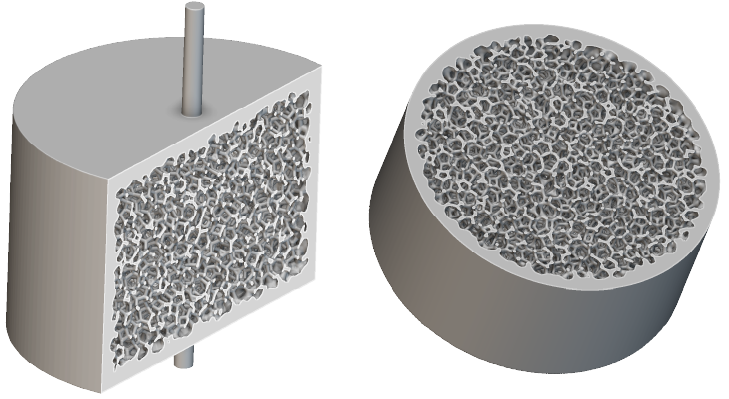

Shown above is one of the designs produced through topology optimization, using nTopology, with the side and top views on the left and right, respectively. This design was created by taking inspiration from crystalline cell structures, and how these unit cells provide order when propogated through materials. The unit cell chosen here was a tetragonal cell structure, chosen because of the benefits it would have for reducing the mass of the rotor, which would improve the rotor efficiency.

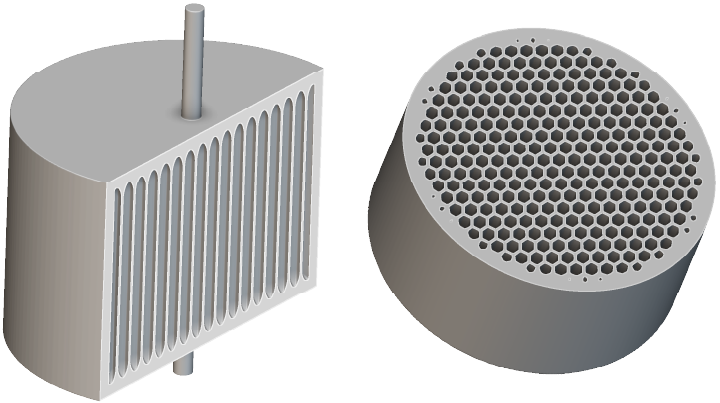

Shown here is the final design created from topology optimization, and was the design that was successfully printed for the culmination of the project. This design was inspired by nature and has a honeycomb structure, which I chose because of the structural integrity that a honeycomb lattice provides, while decreasing the mass and rotational inertia when compared to the original solid design.

Technical Skills required

The technical details required of me in the completion of this project were topology optimization and knowledge of additive manufacturing, both used to create novel rotor designs that could only be 3D printed. Also important was materials selection to improve the magnetic characteristics of our designs as much as possible. Finally, biomimicry was vital in the design process, and was the inspiration for the final rotor design.